About CP Meiji

Production Quality

Always Selecting Fresh Raw Milk

At CP-Meiji factory, we begin each day in the early morning when farmers drive the trucks in after collecting raw milk from fellow farmers to deliver to us. The raw milk that we buy is transported from farms in cool weather area which means we can be confident that it is sourced from healthy and happy cows and every drop retains the freshness as it comes directly from the farm to our place in the morning. The raw milk will then be kept in storage tanks to prepare for processing and making our pasteurized milk full of quality in every cc.

Utilizing Modern,

World-Class Technology

Utilizing Modern,

World-Class Technology

Some of the milk will be processed to produce variety of colors, fragrances and flavors according to CP-Meiji’s secret recipes and become sweetened, chocolate, strawberry and other flavors for a total of over 12 popular flavors. All are rich, aromatic and creamy while still retain authentic taste of cow’s milk that Meiji pasteurized milk fans are all giving thumps up.

Focus on Research and Development for New Product Innovation

Focus on Research and Development for New Product Innovation

Raw milk must pass the weighing and measuring process for residue, fat, quantity, microbes, etc. Every sample of milk must pass the test over and over again for any invisible contaminant to ensure the white liquid milk does not contain any chemical tainting after this process. We confidently warrant that our raw milk is brimming with values that consumers can trust.

Emphasize

Product Quality

Emphasize Product Quality

In the next step, milk will be pasteurized with heat at 72-75 degree Celsius. The temperature is high enough to kill pathogenic microbes but does not destroy the nutritive value of cow’s milk. This process is carried out quickly within just 15 seconds as we want to preserve the taste and freshness of pure cow’s milk. The milk fat molecules will be broken down to make homogeneous and even milk liquid then milk temperature will be quickly cooled down to 4 degree Celsius. After completion of this process, milk will be free of micriobes while every molecule is still packed with protein, calcium, vitamins and delicious taste.

Production Process Certified

by Worldwide Institutes

Production Process Certified by Worldwide Institutes

Pasteurized milk is then brought to cleanroom for bottling in opaque white bottles which protect milk from sunlight and sealed off with foil seal and locked with screw cap by automated machinery which is the most advance technology in Thailand. The meticulous attention in this process will help keep Meiji Pasteurized Milk fresh after bottling. All the milk must then pass the test to verify quantity and quality of package to confirm that each bottle is sufficiently tightly closed and would not leak before reaching consumers’ hands.

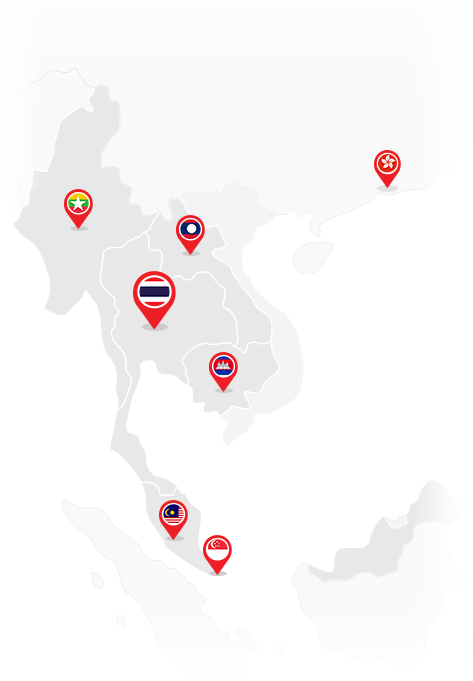

Building the Number 1

Brand and To Be Leader in ASEAN countries

Building the Number 1 Brand and To Be Leader in ASEAN countries

Meiji Pasteurized Milk will be kept in Cold Storage Roomcontrol awaiting the delivery of each bottle from us to you. Milk will be kept at the same cool temperature as in factory cold storage throughout its journey. Every liter and every bottle are transported on daily basis to meet the demand both locally and abroad as freshness cannot wait. CP-Meiji, thus, dedicates full effort in every second to race against time in order to ensure our milk is fresh and well when reaching your hand.